Leave Your Message

Choosing the right Commercial Ice Maker Machine is essential for any business that relies on ice as a critical component of its operations, whether that be in the food and beverage industry, hospitality, or healthcare. A well-suited ice maker not only enhances service efficiency but also ensures high-quality ice production that meets customer demands. As businesses strive to optimize their resources and improve overall productivity, understanding how to select the best ice maker becomes increasingly important.

When embarking on the journey to find the ideal Commercial Ice Maker Machine, various factors must be taken into consideration. These include the volume of ice required, the type of ice that best fits the operational needs, energy efficiency, and the machine's maintenance requirements. Each business comes with its unique demands, and recognizing these nuances is key to making an informed decision. In this guide, we will explore the critical aspects that should be evaluated to find the perfect ice maker for your specific business context, ensuring that your investment leads to improved service delivery and customer satisfaction.

When selecting a commercial ice maker machine, it is essential to understand your business's specific ice production requirements. Start by evaluating the volume of ice you need daily. Consider factors like the size of your operation, the number of customers you serve, and the types of beverages or food items that require ice. This assessment will help determine whether you need a high-capacity ice maker or a smaller model that meets your lower volume needs.

Tips: Always account for peak business hours when assessing your ice needs. This is when ice consumption often spikes, so ensure your machine can handle these surges. Additionally, think about the type of ice you require—different shapes and sizes serve different purposes, from crushed ice for cocktails to larger cube or nugget ice for drinks and food display.

Furthermore, consider the location of the ice maker in your establishment. A machine placed closer to the point of use minimizes labor costs and enhances efficiency. Assessing the available space and ensuring proper ventilation and accessibility for maintenance is crucial for long-term operation. Evaluating these factors will guide you in choosing an ice maker that not only meets your production needs but also fits seamlessly into your workflow.

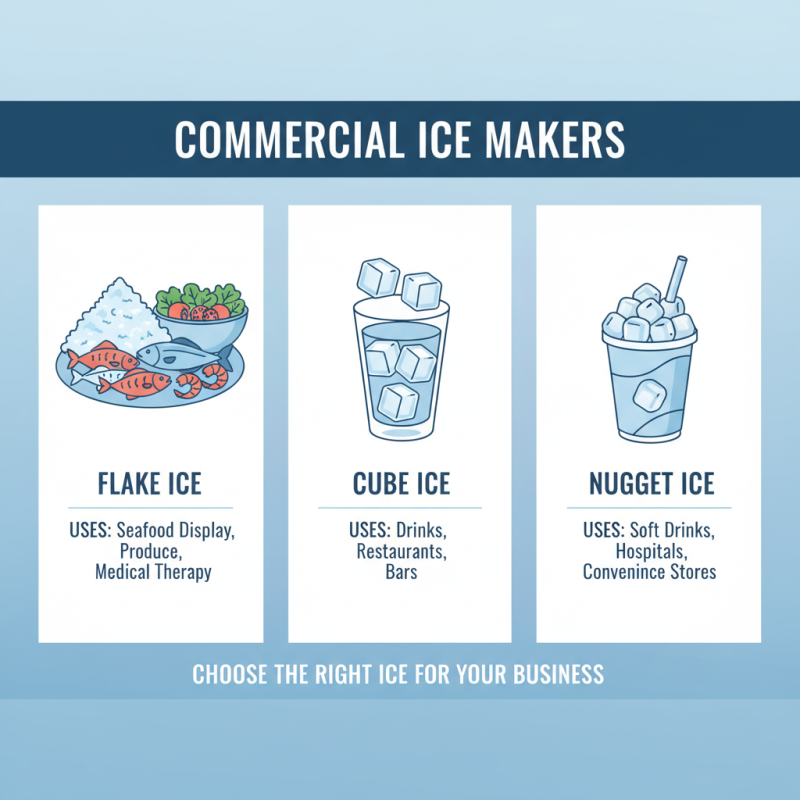

When selecting a commercial ice maker machine, it’s essential to understand the various types available and their specific functions to meet your business needs. The primary types include flake, cube, and nugget ice machines. Flake ice machines produce small, soft ice that is ideal for displaying fresh seafood and produce, keeping them cool and visually appealing. This type of ice is also used in medical facilities for therapeutic applications due to its ability to conform to various shapes.

On the other hand, cube ice machines create uniform-shaped ice cubes, which are perfect for bars and restaurants, providing a classic aesthetic for beverages. They come in various sizes, including full-size and half-size cubes, tailored for different drink types. Nugget ice machines generate chewable ice pellets that are popular in fast-food restaurants and healthcare settings. This ice type retains flavor well, making it an excellent choice for soft drinks and blended beverages. Understanding these types helps businesses choose the most suitable ice maker for their operational purposes, ensuring efficiency and customer satisfaction.

When selecting a commercial ice maker machine for your business, understanding the key features is essential to ensure you meet your operational needs effectively. One vital aspect to consider is production capacity. According to industry reports, choosing a machine with a capacity that aligns with your daily ice usage is crucial; most businesses require anywhere from 50 to 500 pounds of ice daily, depending on their scale and customer volume. Overestimating your needs can lead to unnecessary costs, while underestimating can disrupt service.

Another important feature is the type of ice produced. Different businesses might require specific ice types, such as nugget, flake, or cube ice. For instance, restaurants and bars often prefer cube ice for beverages, while healthcare facilities might opt for flake ice for medical applications. It's essential to assess the specific ice types best suited for your business, as this can impact both customer satisfaction and operational efficiency.

Tips: When evaluating ice makers, consider energy efficiency ratings, as machines with better ratings can significantly reduce electricity costs over time. Moreover, ease of maintenance is crucial; select machines designed for straightforward cleaning and repairs, ensuring minimal downtime. Lastly, pay attention to the warranty and customer support offered, as reliable assistance can save you time and money in the long run.

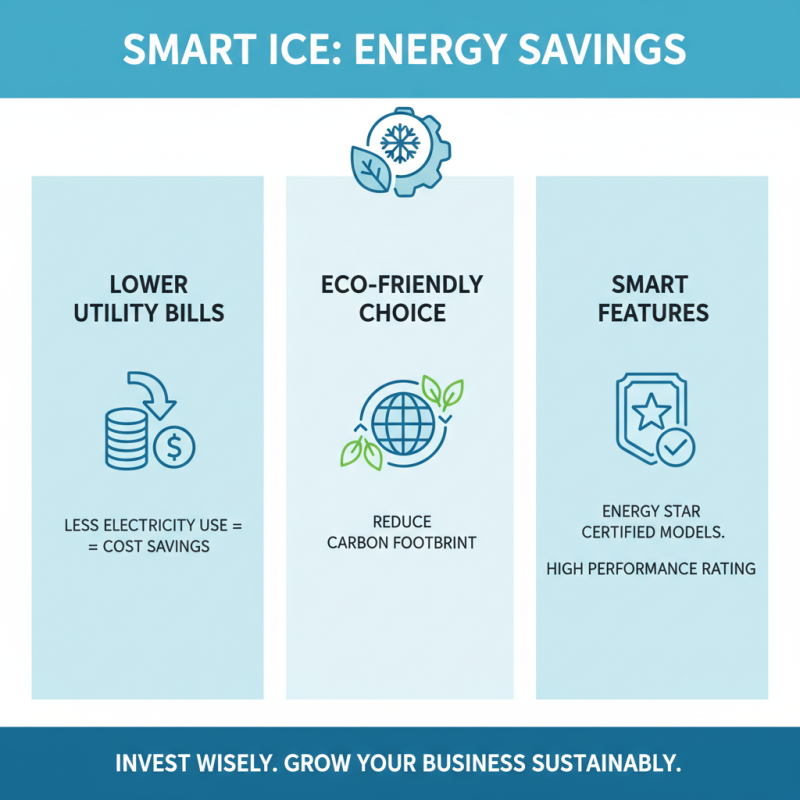

When selecting a commercial ice maker machine, energy efficiency and operating costs are pivotal considerations. An energy-efficient machine not only reduces your carbon footprint but also significantly lowers your utility bills over time. Look for models that are ENERGY STAR certified or have high energy performance ratings. This ensures that the ice maker operates efficiently, using less electricity, which can contribute to substantial cost savings as your business grows.

Tips: Always check the manufacturer's specifications for energy consumption and compare them among different models. Pay attention to the ice production rate while considering energy usage; a machine that produces a large volume of ice while maintaining low energy consumption will be ideal for high-demand businesses. Additionally, consider investing in machines with advanced technology, such as smart sensors that optimize energy use.

Operating costs also encompass maintenance and water usage, which should not be overlooked. Regular maintenance not only enhances the machine's longevity but also helps maintain its efficiency, reducing the likelihood of costly repairs down the line. Understanding the water usage of the ice maker is equally crucial, as some machines utilize more water than others.

Tips: Always review user manuals or consult with suppliers to determine the maintenance requirements of each model. Assessing water and energy costs together can provide a clearer overall picture of the machine's financial impact on your business. By focusing on these factors, you can find a commercial ice maker machine that aligns with both your operational needs and budget constraints.

When selecting a commercial ice maker machine, one of the most critical factors to consider is the brand's reputation. A brand that is well-regarded in the industry typically signals reliability and quality. Researching customer reviews and feedback can provide insight into the machine's performance, durability, and overall user satisfaction. It’s important to look for brands with a history of producing high-quality equipment and those that have a proven track record in the market.

In addition to brand reputation, evaluating customer support options is essential for long-term success. A reputable brand should offer comprehensive customer support, including warranty information, service availability, and responsiveness to inquiries. Businesses should look for manufacturers that provide robust after-sales service and technical assistance to resolve potential issues quickly. Access to knowledgeable support staff can make a significant difference in minimizing downtime and maintaining the efficiency of your ice production.